Hi everyone,

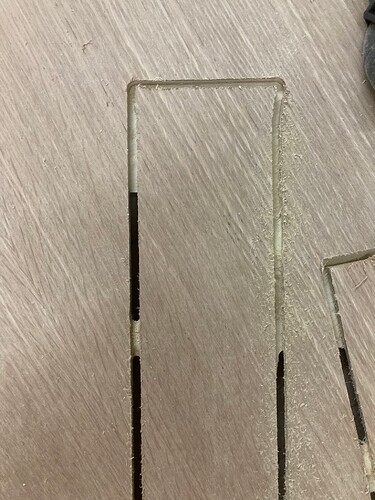

I’ve been testing the goliath all weekend and i’m not getting spectacular results. I have random parts that get very wavy edges. the machine itself starts moving in a jittery manner, randomly. I noticed this, as I was cutting 3/4" furniture grade plywood. i was cutting a series of curves for a jig that come together to make an 8’ (~2.5m) wide arc but the edges were off by a lot (i was doing two layers of staggered parts). And so i started changing depth, speed and rpm… but none of that mattered. it still randomly moves in strange ways, producing inaccurate and low quality parts. out of 7 parts, and 3 times cutting, i only got 2 good and accurate parts.

i saw a similar post and someone suggested that it could be the towers? but the cables don’t feel like they’re catching. i know this is not the drawing file because the rectangle test was drawn directly on slingshot.

my curves were exported from rhino. i also did another version to inskscape and exported svg that way. same results.

Also, i also tried positioning the towers along the short end of the sheet as well as the long end to see if there was a difference… not much. both ways had random places of jittering and waves.